Syllabus⇝

We spend our lives interacting with objects and interfaces who’s underlying technology we hardly understand not merely due to their complexity but also because they were intended to be closed by design.Through the idea of hacking, we will explore the internal components building everyday objects, from coffee machines to wi-fi networks, while learning how to use open software and hardware tools to change the way they work and interface with the world.

Is a practical and intensive two-weeks experimental program into fabrication, physical computing and introduction to the Fab Lab environment. It has been designed to fill knowledge gaps and aimed to prepare students to succeed and improve their experience for rapid prototyping.

We will offer an impact experience, seeking to inspire and motivate the participants to use the possibilities of digital manufacturing and technologies to prototype, design, fabricate and program an “honest” mechanical artifact.

Keywords: Documentation, Tinkering, Design, Prototyping, Digital Fabrication

Learning Objectives⇝

Our active learning methodology is based on the practice and spiral development, designed to encourage the creativity and imagination of the participants, as well as stimulate the search for tools and solutions for their correct definition.

Instrumentation

- Rapid prototyping

- Physical computing

Exploration

- Design maker workflows

- Navigate through the uncertainty

Reflection

- Critical thinking about technologies

- Redesign new systems

Application

- Maker skills

- Hack systems

Materials Needs⇝

All materials needed for the course will be provided by the faculty. The students are required to bring to the classes their own students toolkit and the programming boards given to them at the start of the academic year, other development boards, sensors and actuators will be provided during the workshop.

Bring in your laptop and any prototyping tools you have around such as a cutter, tape, markers, screwdrivers...

Do you have any old appliances (radios, toys, telephones, lamps, screens, keyboards...) at home you would like to take apart? Bring them, too! (For safety reasons, avoid choosing appliances with a lot of power or that are easily heated).

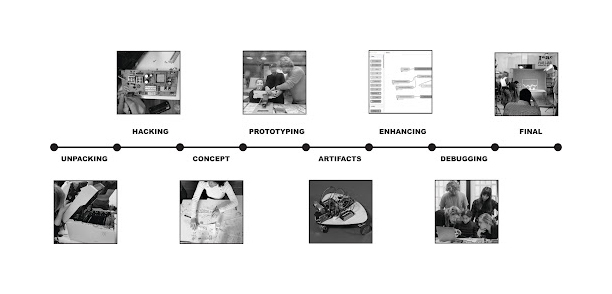

Schedule⇝

The course duration is a total of 32 hours of guided workshop time, spanned along two weeks.

The guided workshop time will happen Tuesday to Friday and the students are committed to work during the afternoon in the projects on a self-guided methodology.

Classes: 09:30 to 13:30 (16 per week)

- Hands-on sessions guided by instructors

Autonomous work: from 14:30 to 18:00 (16 per week)

- Non guided sessions where students work on a task independently or in groups

Group work:

- Non-guided sessions where students work on a task independently or in groups

Tuesday: Presentation & Unpacking (I know what's inside)

Wednesday: Disassemble (I’m not afraid of exploring)

Thursday: Forensic (I know what I have)

Friday: In-Control (I built something I trust)

Tuesday: What to do with these parts (Beta devices)

Wednesday: Integration of artifacts (I build something that works)

Thursday: Field visit & recordings during the afternoon

Friday: Final Presentations(I have a final machine)

Deliverables⇝

Students are requested to submit all the material requested by the faculty + their reflections about the seminar on their personal blog on the MDEF repository on GitHub within a maximum of 1 week after the students’ submission deadline.

In addition, videos and presentations must be submitted in the Submission folder within the seminar's Google Drive folder, which we share with you.

- Write a post out your weekly experience (personal MDEF webpage)

- Deliver the forensic report completely filled

- Add link to the exploration tools and files you produced and used in your repo

- Video and Slide

- Forensic report

Video⇝

- Video at minimun 1080p stabilized (not hand held recordings, use a tripod if you don't know how to stabilize with software)

- BETWEEN 30SEC TO 1MIN

- Open source music matching the artifacts (properly acknowledged).

- Ideally, the sound produced by the machine will also be recorded in the video.

- Entry and finish titles with team names, name of the artifact and Iaac/FablabBCN.

Slides⇝

- Design process (how did you ideate)

- What it is supposed to do or not do

- Ideas or concept in the context

- How is it made (Materials, parts)

- System diagram (illustration explaining function, parts, and relations)

- The coding Logic (Algorithms and flowcharts, pseudocoding)

- Photographies

- Iteration Process

- Learning by Accomplishments and failure

Grading Method⇝

Grading criteria will be defined by faculty during the module.

European Credit Transfer and Accumulation System (ECTS)

5 ECTS

Course Resources⇝

- Hackmd Documentation - Collection of presentations, links and reources for the course.

- Miro Board

- Main Presentation

- TAUMS Showcase

Additional Resources⇝

Bibliography and Background Research Material⇝

They are ordered from shorter to longer so you can start with a short reading essay in your busy schedule

Some of the books can be found online for free, use google and archive.org

Getting Started with Arduino, Banzi, Massimo. Maker Media, Inc, 2008 (ISBN 9780596155513) 128 pages.

Fifty Dangerous Things (You Should Let Your Children Do), Tulley, Gever. Tinkering Unlimited, 2009 (ISBN 9780984296101) 130 pages.

The Design of Everyday Things, Norman, Donald A. Basic Books, 1988 (ISBN 9780465067107) 240 pages.

The Hacker Ethic: and the Spirit of the Information Age, Himanen, Pekka. Random House, 1999 (ISBN 9780375505669) 256 pages.

Hacking Electronics: An Illustrated DIY Guide for Makers and Hobbyists: An Illustrated DIY Guide for Makers and Hobbyists, Monk, Simon. McGraw-Hill/Tab Electronics, 2012 (ISBN 9780071802369) 304 pages.

Designing Reality: How to Survive and Thrive in the Third Digital Revolution, Gershenfeld, Neil. Basic Books, 2017 (ISBN 9780465093472) 304 pages.

How to Diagnose and Fix Everything Electronic, Geier, Michael Jay. McGraw-Hill/Tab Electronics, 2010 (ISBN 9780071744225) 316 pages.

Technology Choice: A Critique of the Appropriate Technology Movement, Willoughby, Kelvin. Intermediate Technology Publications, 1990 (ISBN 9781853390579) 368 pages.

Make It So: Interaction Design Lessons From Science Fiction, Shedroff, Nathan. Rosenfeld Media, 2012 (ISBN 9781933820989) 368 pages.

Building Open Source Hardware: DIY Manufacturing for Hackers and Makers, Gibb, Alicia. Addison-Wesley Professional, 2014 (ISBN 9780133373905) 368 pages.

The Master Switch: The Rise and Fall of Information Empires, Wu, Tim. Knopf, 2010 (ISBN 9780307269935) 384 pages. Dieter Rams: As Little Design as Possible, Lovell, Sophie. Phaidon, 2010 (ISBN ) 398 pages.

To Save Everything, Click Here: The Folly of Technological Solutionism, Morozov, Evgeny. PublicAffairs, 2013 (ISBN 9781610391382) 415 pages.

Adventures in the Anthropocene: A Journey to the Heart of the Planet we Made, Vince, Gaia. Vintage, 2014 (ISBN 9780099572497) 448 pages.

Designing for Emerging Technologies: UX for Genomics, Robotics, and the Internet of Things, Follett, Jonathan. O’Reilly Media, 2014 (ISBN ) 504 pages.

The Innovators: How a Group of Hackers, Geniuses and Geeks Created the Digital Revolution, Isaacson, Walter. Simon and Schuster, 2014 (ISBN 9781476708690) 542 pages.

Designing Interactions [With CDROM], Moggridge, Bill. MIT Press (MA), 2006 (ISBN 9780262134743) 766 pages.

Sites⇝

- hackaday.com is one of the best blogs on DIY inventions and hardware hacking

- lowtechmagazine.com many technology choices are political and economic, looking at past forgotten technologies helps us see the future

- news.ycombinator.com is a social news website focusing on computer science and entrepreneurship.

- archive.fabacademy.org 10 years of project from Fab Labs around the world. Sometimes hard to browse but inspiring!

- learn.adafruit.com a really good site for electronics and programming tutorials, especially for beginners

- instructables more and more DIY tutorials, sometimes aren’t good but there’s a lot

Faculty⇝

Santiago Fuentemilla Garriga , is Master degree in Architecture and postgraduate in digital fabrication and rapid prototyping (Fabacademy). He accumulates more than 15 years of experience in studios (OPR, FHAUS, OPERA, Brullet de Luna associats), designing multidisciplinary projects at an international level. Since 2013 he is part of the IAAC - Fab Lab BCN team, as coordinator and leader of Future Learning Unit (FLU), an area of research, design and implementation of innovative educational models that promote growth, learning and creativity to generate opportunities to achieve the goals and challenges of uncertain futures. FLU participates in private and EU funded research projects such as TEC-LA, Shemakes, Ruractive, DOIT, Phablabs 4.0, Creative Minds, among others. He is director of the global academic programs Fab Academy and Fabricademy, in the Barcelona node, executive board of Fab Learning Academy, and faculty of the Master in Design for Emergent Futures (MDEF) and The Master in Design for Distributed Innovation (MDDI).

Guillem Camprodon is a designer and technologist working in the intersection between emergent technologies and grassroots communities. He is the executive director of Fab Lab Barcelona at the Institute for Advanced Architecture of Catalonia (IAAC), a benchmark in the network of over 2000 Fab Labs and home of the Distributed Design Platform. He has a passion for teaching and is the co-director of the Master on Design For Emergent Futures (MDEF), a collaboration between IAAC and ELISAVA. Previously, he led Smart Citizen, a platform that opposes the traditional top-down Smart City model, empowering communities with tools to understand their environment. As a former research lead, he participated in many European-funded research and innovation projects, such as Making Sense, iSCAPE, GROW Observatory, Organicity, DECODE, ROMI and Reflow.

Daniel Mateos

Digital Fabrication Expert

Multidisciplinary maker and educator with skills in 3D design, 3D printing, metalworking, electronics, programming, biology, and extensive education experience. I have developed careers in the fields of biology, data science, and education. I am currently in transition to employment that uses my skills in digital fabrication, metalworking and electronics. I’m an extremely capable self-learner, very sociable and would love to integrate in a team with shared values to have an impact in the world, preferably at local scale.

Josep Martí is an Industrial Engineer from Barcelona. Josep started his career as a BI consultant but decided to change his professional path graduating from Fabacademy in 2019. Since then, he has taught digital fabrication, design and electronics in the Fablab, being part of the Future Learning Unit teaching in Fabacademy, Fabricademy and the Master in Design in Emergent futures. Recently, he started his path as a researcher in Erasmus+ projects. He holds a Bachelor’s degree in Industrial Technology Engineering and a Master’s degree in Industrial Engineering, specialising in Automatic Control, both from the Polytechnic University of Catalonia (UPC) and the Fabacademy diploma. He has always been interested in the Maker culture and is always looking to learn and create new things.

Petra Garajová

Materials & Textiles

Petra is a Slovak designer with a background in architecture, exploring the boundaries of material science, digital manufacturing and textiles. Currently she is working in Fab Lab Barcelona as a Fabricademy Local Instructor. Her main interest arises from biology and waste materials which lie on the borders of various artistic disciplines. Nowadays, she is also a co-founder of the Experimental Design platform which is using fashion as a tool to reshape the connection between nature, soft materials and the human body using new technologies. Petra holds a Master’s degree in Arts and Architecture at the Academy of Arts Architecture and Design in Prague. After her architectural studies she graduated from Fabricademy – Textile and Technology Academy in Fab Lab Barcelona IAAC. During her studies she was part of Shemakes.eu European project as an Ambassador between Fab Lab Barcelona and TextileLab Iceland working on the Lab to Lab project – Rethinking Wool. Her Fabricademy final project was awarded the Young Scientist Award 2022.

Adai Surinach

Digital Fabrication Expert

Adai graduated with a superior degree in engraving and stamping techniques at Llotja School of Art and Design in Barcelona. After graduation, he became interested in 3D printing, taking him to get involved in Fab Labs until becoming an intern at Fab Lab Barcelona. Shortly after, Adai undertook Fab Academy in 2022 and started working at the lab in different projects like Smart Citizen and as an instructor in academic programs.